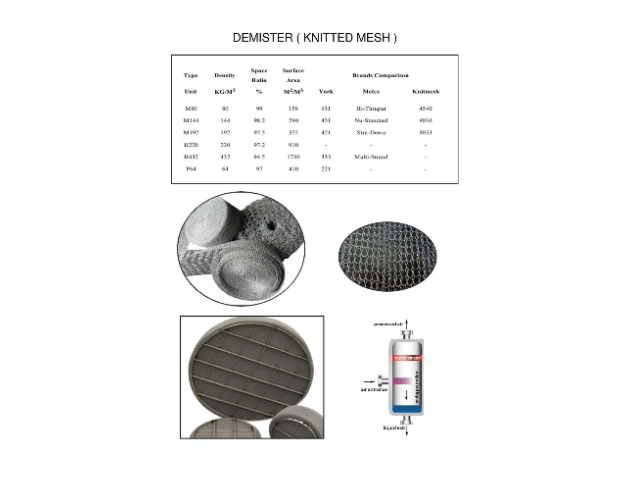

Mist Eliminator

ESZ Company

R&D and production experts specializing in stainless steel wire rods and various metal meshes

不鏽鋼線|不鏽鋼網|金屬網|除霧網|裝潢用網|線纜支架|刺線|輸送網帶|過濾網|平織網|浪形網|菱形網|龜甲網|鐵網|鐵絲網

Recommend using Chrome, Firefox, Safari latest version of the browser.

256 bit SSL Encryption

Designed by MIRACLEWeb Design

- Address158 Si Ning S. Road,Taiepi City 108, Taiwan

- TEL02-2311-7056

- FAX02-2331-9190

- Mailesz.office@msa.hinet.net

- Address408, Sec. 1, Chenggung Road,Guanyin Township, Taoyuan County 328, Taiwan

- TEL03-483-0377

- FAX03-483-0215

- Mailesz.office@msa.hinet.net

不鏽鋼線|不鏽鋼網|金屬網|除霧網|裝潢用網|線纜支架|刺線|輸送網帶|過濾網|平織網|浪形網|菱形網|龜甲網|鐵網|鐵絲網

Recommend using Chrome, Firefox, Safari latest version of the browser.

256 bit SSL Encryption

Designed by MIRACLEWeb Design

ESZ Company

ESZ Company